One of the most useful adjuncts to a motorhome is an awning. On the one hand, they provide shade from the sun, and on the other, they also offer shelter from the rain.

There are a number of manufacturers supplying awnings, which come as self-contained units for attaching to the side of your motorhome.

These are usually deployed using a rotational handle at one end, or by remote control if your budget stretches that far.

Depending on the size required and the level of sophistication you might choose, awnings like these can cost in the region of £50 or more.

As they will require attaching to the side of your motorhome using bolts (and wiring into a power supply in the case of a remote control), there is an added fitting cost (£250+); very few owners will be keen to attack their pride and joy with a cordless drill themselves, let alone muck about with the electrics! So, all up, the cost of fitting an awning can be in the region of £750 upwards.

This article explains how you can construct a rudimentary, but perfectly functional, awning that requires no modifications to your motorhome whatsoever (that is, no drilling of holes), at an all-up cost of about £70.

My costings are for a 3m x 3m tarpaulin and four suction pads. If you require a larger tarpaulin, this will naturally cost more proportionally.

I already have a Fiamma awning on the habitation door side of my ‘van, but I have been on many sites (French aires in the main) where there is plenty of space all around the vehicle.

On such occasions, the awning detailed in this article can be set up on the opposite side of the ‘van as an additional awning, giving extra shade or rain protection and added storage space for chairs, bikes and so on.

Note that this project relies on the use of powerful suction pads. Logic therefore dictates that the awning can only be deployed on ‘vans with a flat, smooth exterior. Some older models have a dimpled exterior, which would render the suction pads ineffective.

The suction pads, according to the manufacturer, will withstand a 20kg loading, which will, with the four I have used, be sufficient to support the tarpaulin in moderate wind conditions.

If greater security is needed, more eyelets can be let into the tarpaulin edge and more suction pads deployed. An additional point of consideration is that areas of the exterior that have any stuck-on wording or decorative flashing should be avoided, because the suction pads might lift these.

Parts required

For a four-suction-pad awning:

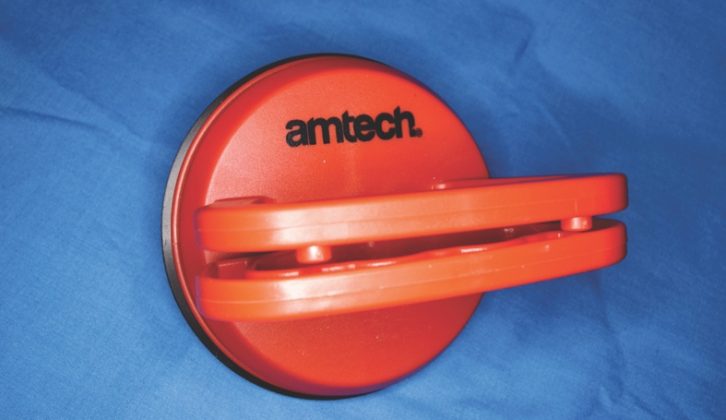

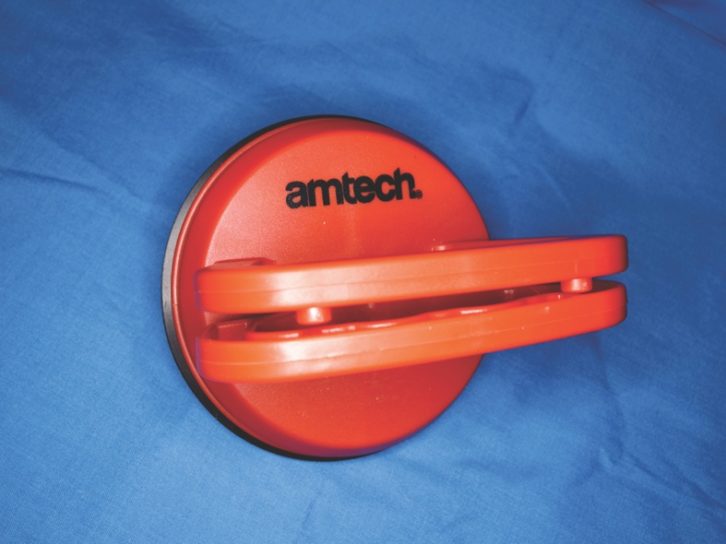

- Four dent-puller/sheet-glass-handling suction pads 120mm diameter

- Aluminium ‘L’ section 60 x 25 x 300mm (or strip if horizontal option is adopted)

- Tarpaulin to suit. Mine was a 3 x 3m. Choose a good quality type (260gsm or better). Mine has a silvered side, which helps to reflect the sun.

- Four tent pegs

- Two tent poles (mine are collapsible 2m variants)

- Two nylon guy ropes (I used Hi-Vis yellow cordage)

- Pole bases (I made these myself using scrap wood)

- A variety of bolts, washers and wiring nuts as shown. These will be exposed to the elements, so I used stainless steel

Tools

- Conventional tool box (screwdrivers, pliers and so on)

- Hacksaw

- Bench vice

- Drills

A step-by-step guide

1. This project used four dent-puller 120mm suction pads.

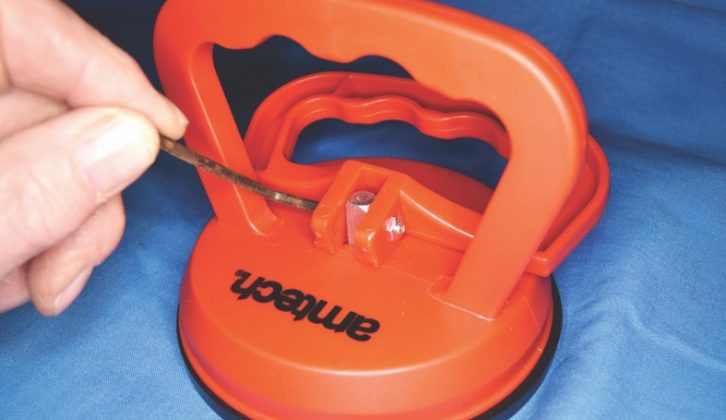

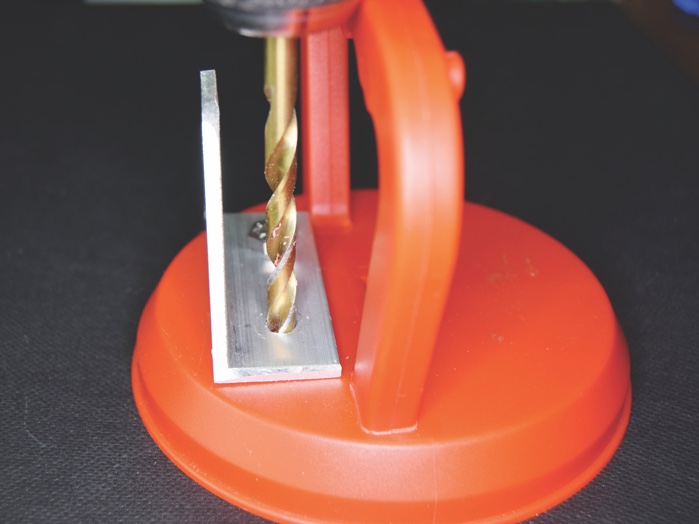

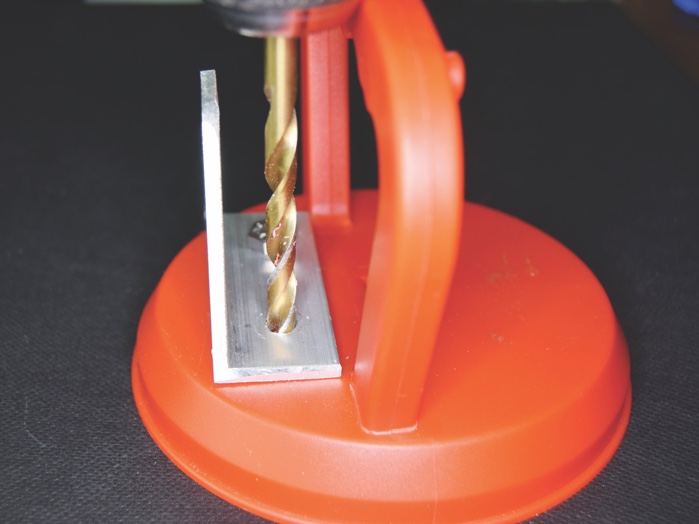

2. Use the bracket as a template and drill 6mm holes as shown. Make sure that the pimples on the handle are as shown.

3. These are the component parts of the stripped-down suction pad.

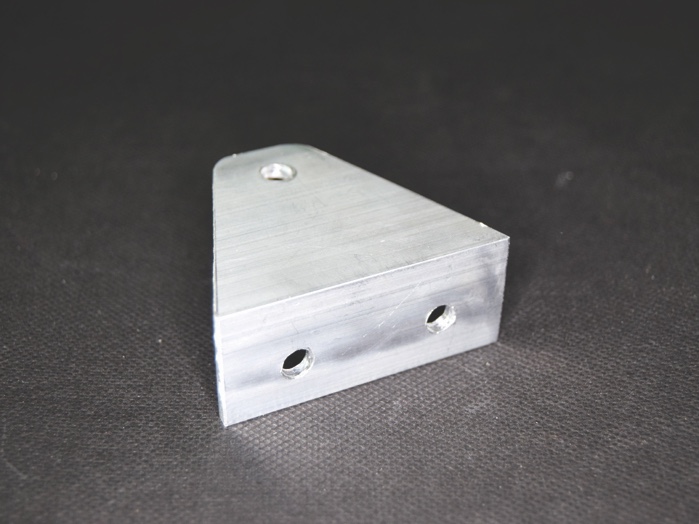

4. Bracket for suction pad that is to be used on a vertical surface (holes are 6mm diameter).

5. Use the bracket as a template and drill 6mm holes as shown. Make sure that the pimples on the handle are as shown.

6. Next, push two M6 x 16 bolts through the suction pad housing with 15mm washers, as shown here.

7. Then secure the bracket using M6 locking nuts and washers.

8. Clamp a 25mm penny washer and two M6 washers using M6 x 25 bolt and M6 nut, as shown here.

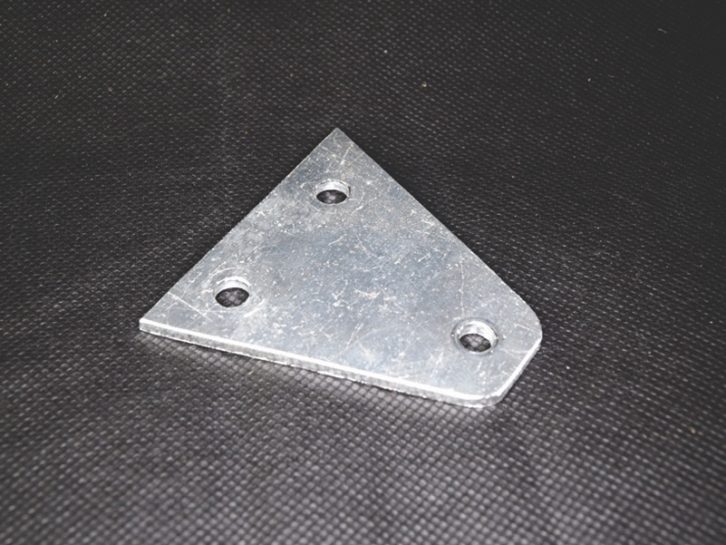

9. Horizontal version can be used to secure tarpaulin to flat roofs and so on.

10. Eyelet clamped by a 25mm penny washer and M6 wing nut. Eyelet should be free to turn; if not, add more washers

11. Suction pads deployed along the side of the ‘van. Wipe area to be used with a damp cloth before attaching.

12. Wooden block securing base of pole.

13. Guy rope showing end designed to go over the pole spike and the tensioner.

14. The fully deployed awning, with no drilling into ‘van sides required!

Caution

Future Publishing Ltd, the publisher of Practical Motorhome, provides the information in this article in good faith and makes no representation as to its completeness or accuracy. Individuals carrying out the instructions do so at their own risk and must exercise their independent judgement in determining the appropriateness of the advice to their circumstances. Individuals should take appropriate safety precautions and be aware of the risk of electrocution when dealing with electrical products. To the fullest extent permitted by law, neither Future nor its employees or agents shall have any liability in connection with the use of this information.

This article explains how you can construct a rudimentary, but perfectly functional, awning that requires no modifications to your motorhome